The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

Lever valves have become an essential component in various industries, driven by their efficiency, reliability, and versatility. According to a recent report by the Global Valve Market Analysis, the global valve market is projected to reach approximately $100 billion by 2024, with lever valves playing a significant role in this growth due to their unique operational advantages. As engineering disciplines continue to evolve, understanding the nuances of lever valves is crucial for optimizing process control and enhancing system performance.

The design and functionality of lever valves are tailored to meet the demanding requirements of modern applications, from fluid control to pneumatic systems. Studies show that industries such as oil and gas, water treatment, and manufacturing are increasingly relying on lever valves for their superior flow regulation and ease of use. As a result, engineers and technicians must familiarize themselves with the specifications, advantages, and potential limitations associated with lever valves to leverage their benefits effectively.

In the context of advancing technologies and automation, the role of lever valves is more critical than ever. The ability to provide quick and reliable manual operation complements sophisticated automated systems, ensuring seamless transitions between manual and automatic controls. Thus, this guide aims to provide a comprehensive overview of lever valves, their applications, and the key considerations for their implementation in modern engineering practices.

Understanding the Basics of Lever Valves: Functionality and Design

Lever valves are integral components in various engineering applications, especially in the automotive and manufacturing sectors. Functionally, these valves manage the flow of fluids or gases by leveraging a simple mechanical movement to open or close passages. Their design varies significantly based on application, yet they share a common principle: converting input force into a controlled output action. According to industry reports, the global demand for valve systems, including lever valves, is expected to reach $90 billion by 2025, demonstrating their critical role in modern engineering.

When considering the design of lever valves, understanding the interplay with the valvetrain is vital. The valvetrain, which comprises components that assist in the regulation of valve operation through the camshaft, ensures precision in timing and efficiency. Recent studies highlight that an optimized valvetrain can lead to a 5-10% increase in engine efficiency, thus underlining the importance of robust lever valve integration.

Tips: Always select the appropriate lever valve for your specific application to ensure optimal performance and longevity. Regular maintenance checks on the valvetrain can prevent costly downtimes by ensuring that the valves are opening and closing correctly. Additionally, consider advancements in materials and design technologies to enhance the efficiency of your valve systems.

Key Features That Differentiate Lever Valves from Other Valve Types

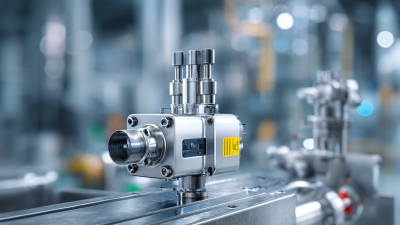

Lever valves are specialized devices that play a crucial role in fluid control within various engineering applications. One of their key features is the mechanism that allows for precise flow regulation through the use of a lever arm. This design not only provides a user-friendly interface but also offers enhanced control compared to traditional valves. By contrast, many other valve types, such as globe or ball valves, may require more complex turning or twisting motions, which can complicate operation and maintenance.

Another notable aspect of lever valves is their capacity for quick actuation. In environments where rapid response is necessary, such as in pneumatic systems or certain hydraulic applications, the lever-operated mechanism allows for immediate adjustments in flow. Additionally, lever valves are often constructed from materials that ensure durability and resistance to wear, further distinguishing them from other types of valves that may not be designed for rigorous service conditions.

This combination of ease of use, responsiveness, and durability makes lever valves an essential choice for modern engineering requirements.

Common Applications of Lever Valves in Modern Engineering Systems

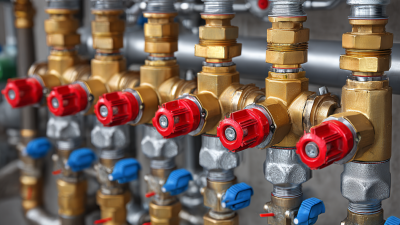

Lever valves are vital components in various modern engineering systems, playing a crucial role in controlling fluid flow. Their mechanical simplicity and reliability make them prevalent in applications ranging from industrial machinery to automotive systems. One common application is in hydraulic systems, where lever valves are used to manage the flow of hydraulic fluid, enabling operators to control machinery with precision. Additionally, these valves are often found in pneumatic systems, regulating air pressure and flow in equipment such as actuators and compressors.

Tips: When selecting a lever valve for your engineering project, consider the specific requirements of your system, including flow rate, pressure levels, and the type of fluid. Choosing the right material for the valve can also impact its performance and longevity, so ensure compatibility with the fluids being used.

Another significant use of lever valves is in water treatment facilities. They facilitate the accurate control of water flow during various treatment processes, ensuring efficiency and safety. Their robustness and adaptability make them suitable for a wide range of environments, from simple irrigation systems to complex wastewater management setups. Understanding the various applications of lever valves can help engineers make informed decisions, optimizing performance in their respective systems.

Tips: Regular maintenance and inspection of lever valves in your system can prevent unexpected failures and prolong their lifespan, ensuring continual operational efficiency.

Advantages of Using Lever Valves in Fluid Control and Automation

Lever valves

have emerged as a critical component in fluid control systems within modern engineering. Their design allows for precise manipulation of fluid flow, making them essential for automation processes. The advantages of using lever valves include enhanced control over fluid dynamics, improved response times, and increased efficiency in various applications. These characteristics make them highly suitable for both linear and part-turn actuator systems.

In industrial settings,

the integration of advanced valve positioners with lever valves elevates their functionality. The combination allows for fine-tuned adjustments and greater reliability in controlling fluid movement. This synergy not only optimizes operation but also reduces wear and tear on equipment, leading to longer service life and lower maintenance costs. As industries continue to adopt automation technologies, the role of lever valves will undoubtedly expand, highlighting their importance in modern engineering solutions.

Future Trends in Lever Valve Technology and Their Impact on Engineering Practices

The landscape of lever valve technology is rapidly evolving, driven by advancements in materials and automation. Recent studies have indicated that the global market for lever valves is projected to reach $3.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.2% from 2022. This growth is largely fueled by the increasing demand for precision control in sectors such as water management, chemical processing, and aerospace engineering. As industries aim to enhance efficiency and reduce downtime, the integration of smart technology into lever valves is becoming a prominent trend.

Moreover, innovations such as IoT connectivity are expected to revolutionize the way engineers interact with these valves. With predictive maintenance and real-time monitoring capabilities, engineers can preemptively address issues, thereby minimizing operational risks. According to a report by Frost & Sullivan, the adoption of digital solutions in valve technology can reduce maintenance costs by up to 30% and improve system efficiency by 25%. As we move into an era where sustainability is paramount, the further development of eco-friendly materials in lever valves is also anticipated to play a crucial role in shaping future engineering practices.

Related Posts

-

Discover the Benefits of Using Butterfly Valves in Industrial Applications

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Understanding the Role of Combination Valves in Modern Plumbing Systems: A Comprehensive Guide

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights