2026 How to Choose the Right Automatic Valve for Your System?

Choosing the right automatic valve for your system is crucial. An unsuitable valve can cause inefficiencies and costly repairs. There are many types of automatic valves, and each serves a specific purpose.

Consider the environment where the valve will be used. Factors like temperature and pressure play significant roles. Will the valve handle corrosive substances or high flow rates? Each scenario demands careful thought. You cannot rush this decision; it requires research and attention to detail.

Not every automatic valve will fit every system. Sometimes common choices may not work as expected. Look beyond brands and specifications. Focus on the unique needs of your system. Ask experts, gather information, and reflect on your specific requirements. Choosing wisely will lead to better performance and longevity.

Understanding the Basics of Automatic Valves and Their Applications

Automatic valves play a crucial role in many systems. They manage the flow of fluids efficiently. Understanding their types and applications is essential for making the right choice. For instance, solenoid valves are commonly used in automation. They respond quickly and can control fluids precisely.

Tips: Consider the environment where the valve will be installed. Conditions like temperature and pressure matter. Choose materials that withstand these factors. A valve may seem perfect, but it could fail in extreme conditions.

Another important factor is the flow medium. Different fluids require different types of valves. For example, corrosive fluids need specialized materials. A regular valve might not perform well and could lead to leaks.

Tips: Always assess the system's requirements. Is the flow rate consistent? Does it require frequent adjustments? Understanding these will help you choose wisely. Valves can sometimes be more complex than they appear. Careful evaluation prevents future headaches.

2026 How to Choose the Right Automatic Valve for Your System?

This chart illustrates the various types of automatic valves used in different applications and their respective market share as of 2026. Understanding these distributions will help in selecting the right valve for your system.

Types of Automatic Valves: Selecting the Right Type for Your Needs

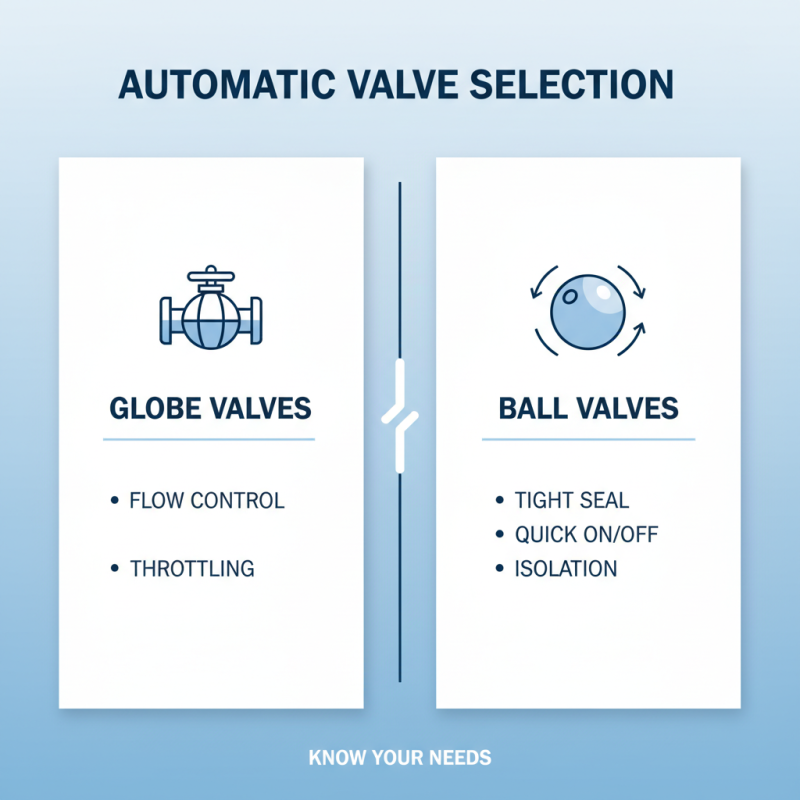

When selecting the right type of automatic valve, understanding your needs is crucial. Several types exist, each serving unique purposes. For controlling flow, globe valves work well. They offer excellent throttling capabilities. On the other hand, ball valves provide a tight seal and quick operation. They are ideal for on-off applications.

Consider your system’s pressure and flow rate when choosing. Pressure affects how well the valve performs. Too much pressure might lead to failures. Similarly, flow rates can dictate the size of the valve. A mismatch can lead to inefficiency or damage.

Don't forget about maintenance needs. Some valves require more care than others. Regular checks can help prevent issues. Automatic valves often come with complex mechanisms. Sometimes, simplicity is more effective. Reflecting on these factors can lead to better decisions. Choosing the right valve might seem straightforward but requires careful thought.

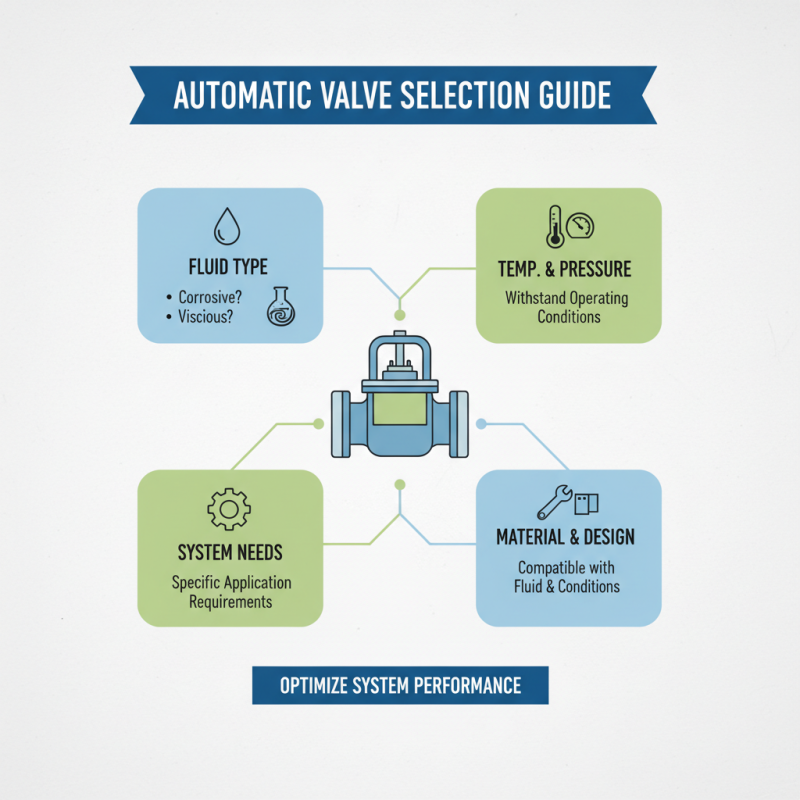

Key Factors to Consider When Choosing Automatic Valves

When selecting an automatic valve, consider the system’s specific needs. The type of fluid being handled matters significantly. Is it corrosive or viscous? This choice impacts valve material and design. Pressure and temperature ratings are also crucial. Ensure the valve can withstand the operating conditions effectively.

Actuation is another key factor. Pneumatic, electric, or hydraulic options exist. Each has benefits and drawbacks. Think about the power source available. Consider the required response time too. Some systems demand fast actions, while others do not. Valves must fit into the existing infrastructure.

Maintenance is often overlooked. Automatic valves require periodic checks to prevent failures. Build a maintenance schedule into your operational plan. Regular inspections can save costs in the long run. Keep in mind, even the best valve might not perform flawlessly. Over time, parts wear out and require replacements. Consider all these factors carefully. Making the right choice isn’t easy. Mistakes can happen, but learning from them can lead to better decisions in the future.

How Valve Specifications Affect Performance and Efficiency

Choosing the right automatic valve requires careful consideration of valve specifications. These specifications significantly impact the performance and efficiency of your system. Valves control the flow of fluids, and even minor changes can lead to inefficiencies.

The size of the valve is crucial. An incorrectly sized valve can create turbulence, affecting flow rates. This can cause pressure drops that lead to wasted energy.

Material selection is another key factor. Different materials react differently under various temperatures and pressures. Inadequate material choices can lead to premature failure. You may find that some materials corrode faster than others. Additionally, operating conditions must be considered. High temperatures can change how a valve performs over time. Regular maintenance is essential. Neglecting this can diminish valve efficiency, leading to costly repairs.

Lastly, control methods should not be overlooked. Different systems may require specific control techniques. For instance, pneumatic versus electric controls can produce varying results. The effectiveness of these controls can fluctuate based on the setup. It's essential to evaluate how these elements interact within your system. The goal is to enhance efficiency while minimizing downtime.

Installation and Maintenance Tips for Optimal Valve Functioning

When selecting the right automatic valve, installation and maintenance play crucial roles. Proper installation ensures optimal performance and longevity. Start by checking the alignment of pipes and supports. Misalignment can lead to leaks and failure. Always ensure gaskets and seals are intact during installation. This prevents unwanted leaks that could disrupt your system.

Routine maintenance is equally important. Regularly inspect valves for signs of wear. Check for leaks around seals and connections. Keep the valve body clean and free of debris. Sometimes, maintenance is overlooked. System downtime can occur when valves fail. Therefore, create a maintenance schedule. This will help ensure the valves function correctly over time.

Remember, not all systems are the same. Each requires specific attention. Identify the unique needs of your system. Some valves may need more frequent checks than others. Staying proactive in maintenance helps to reduce unexpected repairs.

2026 How to Choose the Right Automatic Valve for Your System? - Installation and Maintenance Tips for Optimal Valve Functioning

| Valve Type | Suitable Applications | Installation Tips | Maintenance Recommendations |

|---|---|---|---|

| Ball Valve | On/Off Control in Water & Gas | Ensure proper alignment during installation. | Inspect seals annually; replace worn parts. |

| Gate Valve | Waterworks and Oil Distribution | Install in a horizontal position for best performance. | Regularly check for rust and corrosion. |

| Butterfly Valve | Throttling in HVAC Systems | Ensure adequate space for actuator clearance. | Lubricate bearings every 6 months. |

| Check Valve | Prevent Backflow in Pipelines | Install in vertical position for optimal flow. | Inspect for blockages quarterly. |

| Solenoid Valve | Automated Fluid Control | Verify electrical connections before installation. | Test electrical circuit bi-annually. |

Related Posts

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

What is a Lever Valve? Understanding Its Types and Applications

-

How to Choose the Right Valve for Your Plumbing Needs?

-

How to Choose the Right Pilot Valve for Your Application?

-

Why You Should Choose Automatic Valves for Your Industrial Applications