Why are Flow Valves Essential in Industrial Applications?

Flow valves play a pivotal role in various industrial applications. They control fluid flow, ensuring efficiency and safety. According to a report by MarketsandMarkets, the global flow valve market is projected to reach $80 billion by 2025. This growth highlights the increasing importance of these components in sectors like oil and gas, water treatment, and manufacturing.

John Smith, an expert in fluid dynamics, states, “Flow valves are the backbone of any efficient fluid system.” His insight reflects how essential these valves are for regulating system pressures and volumes. In many industries, improperly functioning flow valves can lead to costly downtimes and hazardous situations.

Yet, there are challenges. Many companies overlook regular maintenance of flow valves. This oversight can lead to unexpected failures and increased operational costs. Understanding the significance of flow valves can drive improvements in industrial processes. Investing in quality valves and maintenance is crucial. Ignoring this can have serious repercussions.

The Role of Flow Valves in Regulating Industrial Fluid Dynamics

Flow valves play a critical role in managing fluid dynamics within industrial systems. These components control the flow rates, pressure, and direction of fluids, ensuring that processes run smoothly. According to a 2022 industry report, nearly 30% of production downtime results from fluid mismanagement. This highlights the importance of effective flow regulation.

In many facilities, flow valves significantly impact energy efficiency. In fact, improper valve function can lead to energy losses of up to 25%. For instance, when a valve fails to close fully, it can cause leaks, wasting not only resources but also money. The improper use of flow valves can disrupt operations, leading to cascading failures. Regulators often recommend regular maintenance checks, but studies show that up to 40% of companies fall short in this regard.

Choosing the right flow valve requires careful assessment. Factors such as fluid type, temperature, and pressure must be considered. Generally, industries overlook these details and suffer the consequences later. For example, a valve that isn’t well suited for the application can increase wear and tear on equipment. This makes training and awareness crucial within operational teams. Understanding how flow valves influence overall system dynamics helps in preventing costly mistakes.

Types of Flow Valves Used in Various Industrial Applications

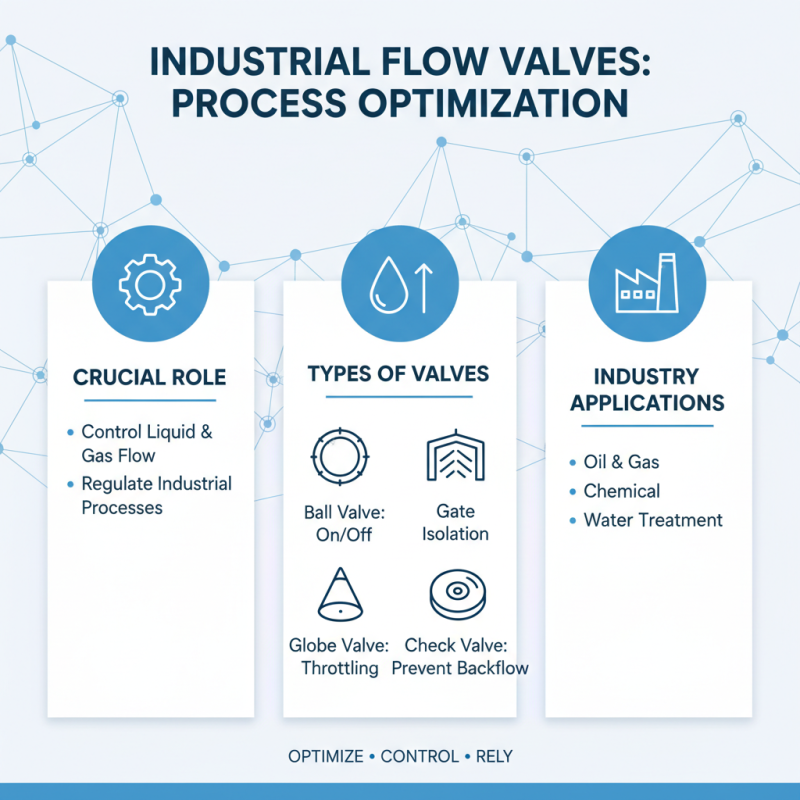

Flow valves play a crucial role in various industrial applications. They are vital for controlling the flow of liquids and gases. Understanding the types of flow valves can help optimize processes. Many industries rely on specific designs tailored to their needs.

One common type is the globe valve. They manage the flow with precise control. This valve has a spherical body and a movable disk. They are often used in cooling systems and water piping. Another type is the ball valve. Known for quick on-off control, they are found in gas and oil applications. Their simple design makes maintenance easier.

Tips: Regularly inspect your valves. Look for leaks or wear. Replace any damaged parts promptly. This can prevent expensive downtime.

Consider also check valves, which allow fluid to flow in one direction. They prevent backflow, crucial in many systems. Ensure these are installed correctly. Misalignment can lead to failures. Each valve type serves a precise function, but installation must be equally considered for optimal performance.

Key Advantages of Using Flow Valves in Industrial Systems

Flow valves play a vital role in industrial applications. They control the flow of liquids and gases. This control is crucial for maintaining system efficiency. Various industries rely on flow valves for their operations. The advantages of using these valves are significant.

One key benefit is enhanced safety. Flow valves help prevent accidents caused by overpressure or leaks. They regulate the flow effectively, reducing risks. Valves can also help save energy. By controlling the flow rates, systems operate more efficiently. This leads to lower operating costs.

Tips: Regular maintenance is essential. Inspect flow valves periodically for wear and tear. A small issue can lead to bigger problems. Choose the right valve type for your specific application. Not all valves are created equal.

Flexibility is another advantage. Flow valves can adapt to different conditions. They can handle varying pressures and temperatures. This adaptability makes them suitable for many applications. However, ensure that the chosen valve matches your system requirements. It’s not always easy to find the perfect fit. Stay informed and keep refining your choices for better outcomes.

Challenges and Considerations in Flow Valve Selection

Selecting the right flow valve can be challenging. Various factors influence the decision. Fluid type, pressure, and temperature play crucial roles. A report from the International Society of Automation highlights that incorrect valve selection can lead to a 20% increase in operational costs due to inefficiencies.

Material compatibility is another concern. Using the wrong materials can lead to corrosion and leakage. According to a survey by Chemical Engineering, nearly 30% of facilities experience issues related to valve material miscalculations. Many professionals overlook this aspect, leading to significant downtime.

Also, actuator type must be considered. Manual valves may not suit high-demand environments. Electric or pneumatic actuators increase reliability but add complexity. Companies often struggle to balance performance with maintenance needs. Understanding how each component affects overall functionality is vital for effective decision-making.

Future Trends in Flow Valve Technology for Industrial Use

The evolution of flow valve technology is shaping the future of industrial applications. As industries seek higher efficiency, flow valves are becoming smarter. These advancements focus on automation and real-time monitoring. Enhanced sensors provide precise data on flow rates. This means better control, leading to energy savings and reduced operational costs.

Another trend is the integration of IoT with flow valves. This allows for remote monitoring and predictive maintenance. However, there are challenges. Not all systems are compatible, and implementation can be costly. Companies must weigh the benefits against the investment. Additionally, cybersecurity risks are a growing concern. Protecting data becomes crucial as more devices connect to the network.

Sustainability is also driving innovation. Manufacturers are exploring eco-friendly materials and designs. These advancements are promising but can lead to untested solutions. It’s essential to consider how these materials impact performance in real-world conditions. As we move forward, finding the balance between innovation and reliability will be key. The landscape of flow valve technology is changing rapidly. The future seems bright, but challenges remain.

Related Posts

-

Top 10 Valve Home Innovations to Watch in 2025

-

2025 How to Choose the Best Valve Products for Your Industry Needs

-

Why You Should Choose Automatic Valves for Your Industrial Applications

-

Top 5 Home Valve Solutions to Improve Your Plumbing Efficiency

-

Best Home Valves for Energy Efficiency in 2023 Based on Industry Data

-

How to Choose the Right Gas Valves for Your Home or Business Needs