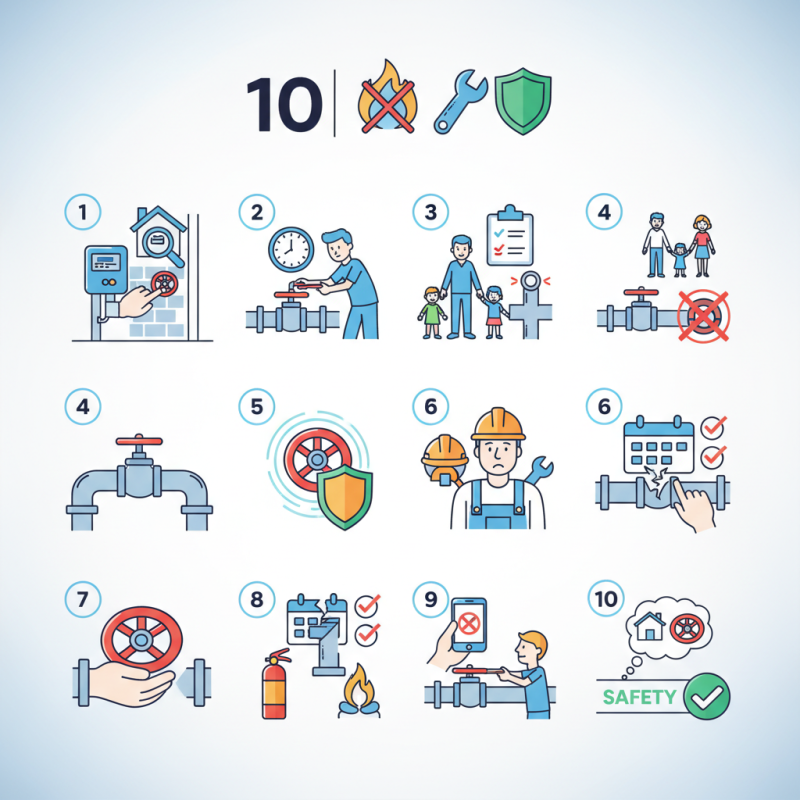

10 Essential Tips for Using a Gas Shut Off Valve Safely

Gas shut off valves are crucial for safety in any home or business. They can prevent dangerous leaks and potential disasters. Knowing how to use these valves is essential. Many people overlook their importance. They might not grasp when or how to operate them effectively.

Understanding your gas shut off valve is vital. Many homes have them, yet few know how to locate them. When a gas leak occurs, every second counts. You may need to act quickly. Practice turning off the valve with family members. This simple step can save lives.

It is also important to check the condition of your valve regularly. Wear and tear can make them ineffective. A valve should not be rusted or stuck. If it is, seek professional help. Safety should always be a priority. Familiarity with your gas shut off valve can be a lifesaver. Ignoring its maintenance can lead to catastrophic results.

Understanding the Purpose and Function of Gas Shut Off Valves

Gas shut off valves are crucial for safety in gas systems. These valves stop gas flow when needed, preventing leaks and hazards. When you turn a valve, it blocks the gas line. This function is essential during emergencies, repairs, or system maintenance.

Understanding the purpose of these valves helps prevent accidents. Many people overlook their importance. A valve that doesn’t work can lead to dangerous situations. Regular checks are necessary to ensure they function correctly. If a valve is stuck or damaged, it may not close completely.

Make a habit of familiarizing yourself with the gas shut off locations. Sometimes, people forget where these valves are placed. In an emergency, seconds matter. Knowing how to operate them can save lives. The valve handling process should be practiced, especially in homes with children or pets. If you're unsure, seek professional assistance for proper usage.

Identifying the Different Types of Gas Shut Off Valves

When dealing with gas shut-off valves, understanding the types available is crucial. There are several kinds, from manual to automatic. Manual valves require physical operation to shut off gas flow, while automatic valves detect leaks and act without user input. According to the National Fire Protection Association, a significant number of gas accidents stem from improper valve usage or failure to shut them off correctly.

In residential settings, the most common type is the ball valve. These are known for their durability and ease of use. However, their reliability can be impacted by wear and tear. Regular inspections are necessary to ensure they function as intended. Reports show that nearly 25% of gas incidents occur due to neglected valve maintenance. On the other hand, solenoid valves are often used in commercial settings. They provide a quicker response, but incorrect installation can lead to vulnerabilities.

Knowing when and how to operate these valves is essential. Many people overlook this aspect during safety training. Common mistakes include failing to familiarize oneself with the valve location or the specific handling techniques required. Visual aids and regular drills could improve overall safety. The lack of knowledge can lead to hazardous situations, highlighting the need for better education around gas shut-off valves.

Step-by-Step Guide to Locating Your Gas Shut Off Valve

Locating your gas shut-off valve is crucial for safety. Start by checking near your gas appliances or in the basement. In homes, it's often placed in the utility room. Look for a round or lever-style valve, typically made of metal. Knowing its location can help in emergencies.

When you find the valve, mark it clearly. Use a piece of tape or a label. This simple action can save time during a crisis. Ensure everyone in the household knows where it is.

Tips for using the gas shut-off valve safely include turning it off during long absences. This reduces risks from leaks. Observe it regularly for any signs of wear or damage. If the valve is stiff, avoid using excessive force. Over time, even a sturdy valve can become problematic. Regular checks can prevent emergencies.

Safety Precautions to Take Before Operating a Gas Shut Off Valve

Before operating a gas shut off valve, ensuring safety is vital. Familiarize yourself with the valve location. It’s often found near appliances, but some homes might have them buried in walls or basements. Look for labels or markings. If not visible, consult a maintenance manual or a knowledgeable person.

Next, inspect the area around the valve. Keep it clear of clutter. Remove any flammable materials nearby. A clean space reduces risks. Before touching anything, wear appropriate safety gear like gloves. They won’t protect against every hazard, but a little extra caution helps.

If you're unsure about the valve's operation, seek guidance. DIY can go wrong. Gas systems are complex, and mistakes can have serious consequences. Taking time to verify your approach is essential. Always adhere to safety protocols, and if necessary, contact a professional. It may feel tedious, but it can make all the difference.

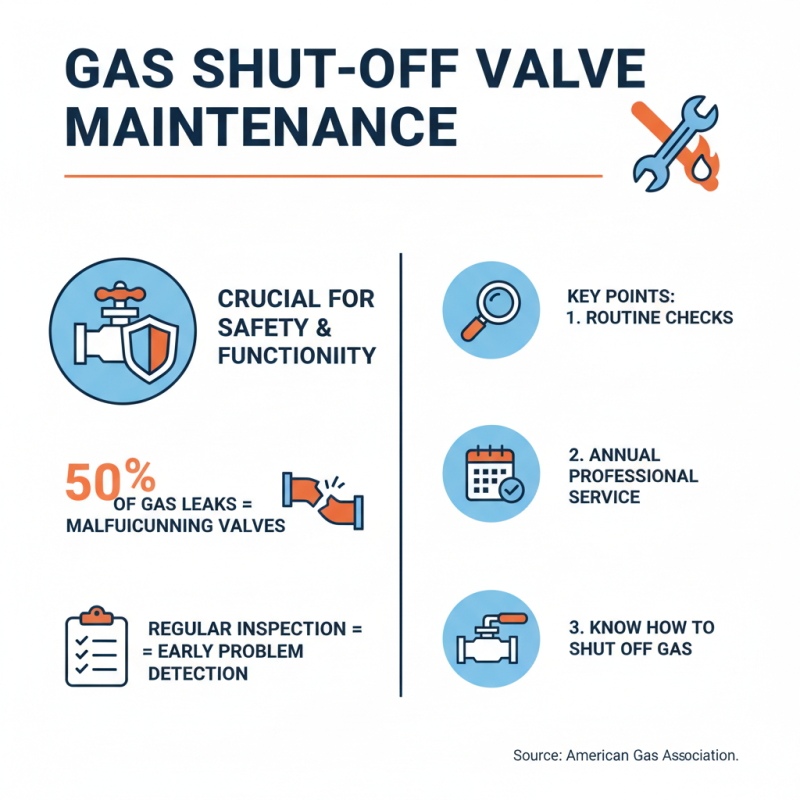

Regular Maintenance Tips for Ensuring Valve Functionality and Safety

Regular maintenance of gas shut-off valves is crucial for ensuring safety and functionality. According to the American Gas Association, nearly 50% of gas leaks are attributed to malfunctioning valves. Regular inspection can help in identifying issues early.

Inspect your gas shut-off valve at least once a year. Look for rust, corrosion, and loose fittings. A simple visual check can reveal potential problems. If there are signs of wear, consider replacing the valve immediately. It’s a small investment compared to the risk of a gas leak.

Keep the area around the valve clear. Avoid clutter that could obstruct access. In case of emergencies, swift action is vital. Additionally, practice periodic testing of the valve's functionality. Turn the valve on and off to ensure it operates smoothly. If it feels stiff or unresponsive, it might require professional attention. Regular care can mitigate risks effectively.

Related Posts

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

How to Choose the Right Gas Valves for Your Home and Business Needs

-

10 Essential Tips for Locating and Operating Your Natural Gas Shut Off Valve

-

How to Choose the Right Gas Valves for Your Home or Business Needs

-

Top 10 Important Facts About Natural Gas Shut Off Valve You Need to Know

-

Top Gas Valves: Essential Types, Uses, and Buying Guide