How to Choose the Right Lever Valve for Optimal Fluid Control in Industrial Applications

In industrial applications, the selection of the appropriate lever valve is crucial for ensuring optimal fluid control, efficiency, and safety. Lever valves, known for their simplicity and ease of operation, have become indispensable components in various sectors, including oil and gas, water treatment, and manufacturing. According to a report by Markets and Markets, the global valve market is projected to reach USD 93.4 billion by 2026, with an increasing focus on leveraging advanced fluid control technologies. This highlights the significant role that lever valves play in optimizing fluid dynamics across diverse industries.

Choosing the right lever valve involves understanding the specific fluid characteristics, pressure conditions, and operational requirements of an application. As outlined by the Fluid Control Association, implementing the correct valve type can enhance system performance and reduce operational costs by up to 20%. Additionally, with the rise of automation in industrial processes, the integration of high-quality lever valves can lead to improved responsiveness to system demands. This introduction will guide professionals in making informed decisions that not only meet regulatory standards but also drive efficiency and reliability in their operations.

Understanding Lever Valve Types and Their Applications

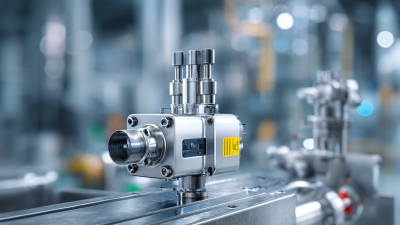

When selecting the right lever valve for optimal fluid control in industrial applications, it's essential to understand the various types and their specific applications. Lever valves come in a range of configurations, including ball valves, gate valves, and butterfly valves, each designed for distinct operational needs. According to a report published by Market Research Future, the global valve market is expected to reach $109 billion by 2025, driven in part by advancements in precision fluid control technologies.

Ball valves, known for their durability and tight seal, are typically used in applications requiring immediate on-off control. In contrast, gate valves are more suited for applications that demand uninterrupted flow when fully open, making them ideal for high-volume transport. Meanwhile, butterfly valves provide quick closure and are often utilized in systems requiring space-efficient solutions, especially in water treatment and chemical processing industries. As industries evolve and new standards emerge, understanding the specific functionalities of each lever valve type ensures efficient operation and can significantly influence overall system performance.

How to Choose the Right Lever Valve for Optimal Fluid Control in Industrial Applications

| Lever Valve Type | Application | Operating Pressure (psi) | Material | Flow Rate (GPM) |

|---|---|---|---|---|

| Ball Lever Valve | Water Treatment | 150 | PVC | 25 |

| Butterfly Lever Valve | Chemical Processing | 200 | Stainless Steel | 50 |

| Gate Lever Valve | Oil and Gas | 300 | Carbon Steel | 100 |

| Check Lever Valve | Pumping Stations | 250 | Bronze | 75 |

| Globe Lever Valve | HVAC Systems | 150 | Ductile Iron | 20 |

Key Factors to Consider When Selecting a Lever Valve

When selecting a lever valve for optimal fluid control in industrial applications, several key factors must be considered to ensure efficiency and reliability. First, the valve material is crucial; it must be compatible with the fluid being handled. According to a report by the International Journal of Fluid Mechanics, over 25% of industrial failures are attributed to corrosion and material incompatibility. Choosing materials like stainless steel or PVC can significantly enhance durability and reduce maintenance costs.

Another important factor is the valve size and flow rate. The American Society of Mechanical Engineers (ASME) emphasizes that improper sizing can lead to pressure drops and inefficient flow, potentially wasting up to 30% of energy in pumping systems. Ensuring the lever valve meets the specific flow requirements of the application will not only optimize performance but also improve the overall efficiency of the system. Evaluating these factors carefully can lead to better operational outcomes and cost savings in the long run.

Lever Valve Selection for Fluid Control Performance

Comparison of Manual vs. Automated Lever Valves

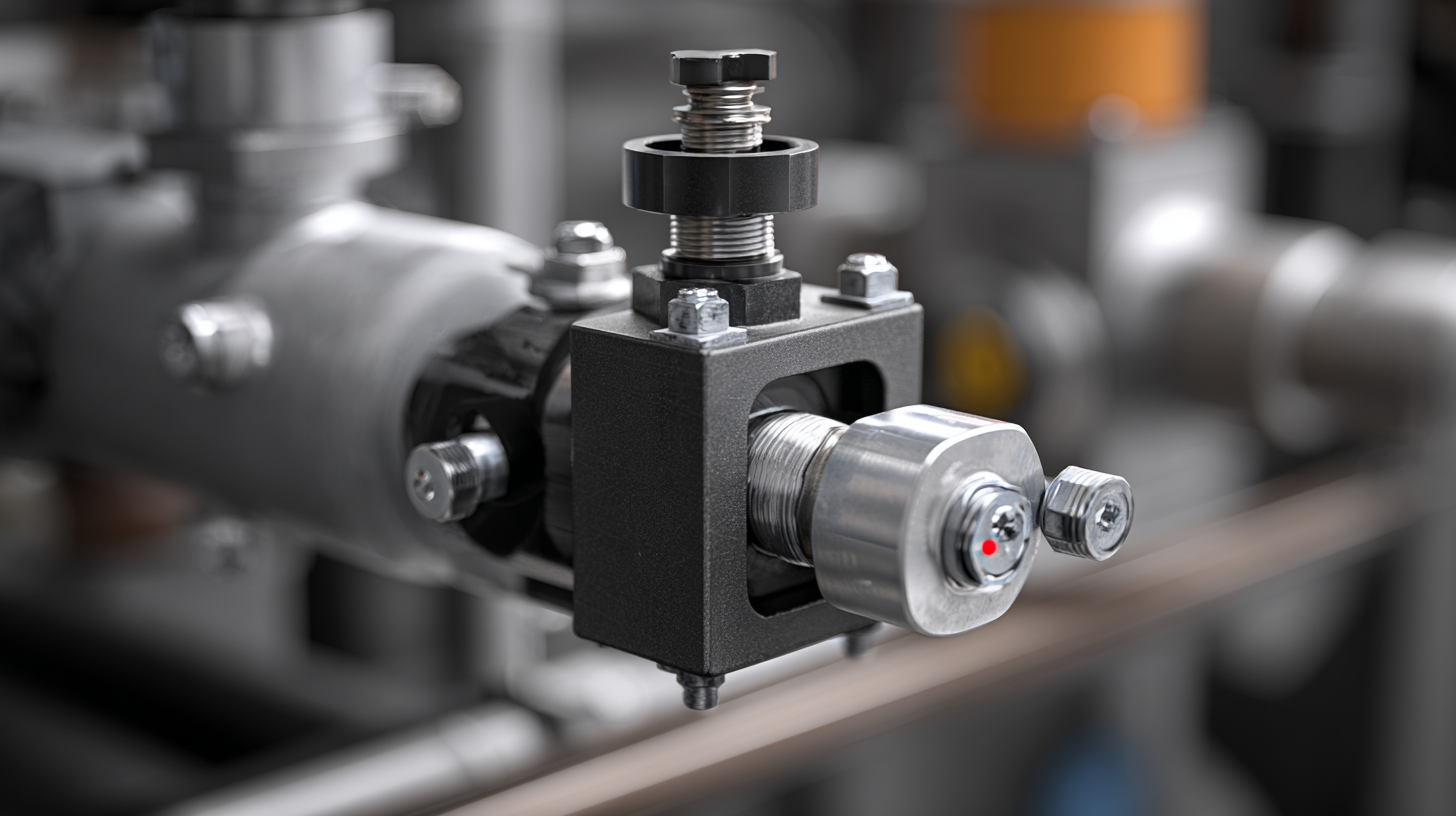

When selecting the right lever valve for fluid control in industrial applications, one key consideration is the choice between manual and automated lever valves. Manual lever valves offer simplicity and ease of use. Operators can physically manipulate the valve to control flow, providing direct feedback and immediate adjustment capabilities. This type of valve is often favored in environments where quick visual checks and manual oversight are crucial, allowing for straightforward maintenance and operational flexibility.

On the other hand, automated lever valves present numerous advantages in terms of efficiency and precision. These valves utilize actuators to automate the opening and closing processes, which enhances throughput and minimizes human error. Automation is particularly beneficial in high-volume operations or hazardous environments, where constant human intervention may pose risks. Moreover, automated systems can be integrated into broader control networks, enabling real-time monitoring and data collection. Thus, the decision between manual and automated lever valves should be guided by the specific requirements of the application, including factors like operational scale, safety concerns, and desired levels of control.

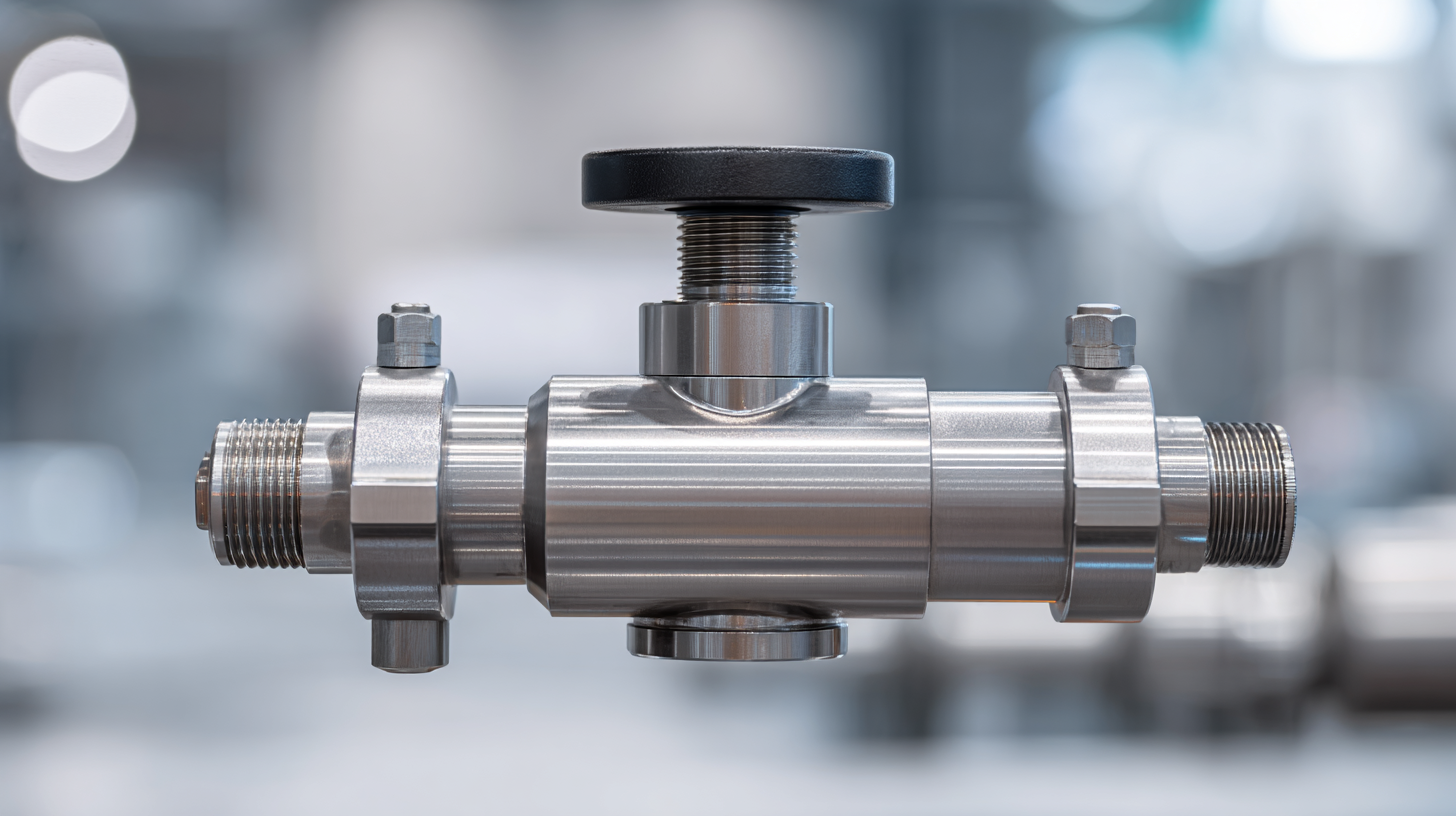

Common Materials and Designs for Lever Valves

When selecting a lever valve for optimal fluid control in industrial applications, understanding the common materials and designs is crucial. Lever valves are typically made from materials such as brass, stainless steel, and PVC, each offering distinct advantages based on the application requirements. According to a report by the International Fluid Power Society, brass valves are commonly favored in low-pressure applications due to their resistance to corrosion and ease of machinability, making them ideal for water and air services. Conversely, stainless steel valves are preferred in high-pressure and high-temperature environments, particularly in oil and gas industries, where durability and reliability are paramount.

The design of lever valves also varies significantly, impacting their functionality in different settings. Common designs include full-port and reduced-port configurations. Full-port designs allow for maximum flow with minimal pressure drop, which is essential in large-scale industrial systems, while reduced-port designs can be more cost-effective in smaller systems where flow rate isn’t as critical. A study published in the Journal of Mechanical Engineering revealed that selecting the correct valve design could lead to efficiency improvements of up to 20% in fluid control applications. Thus, understanding both material composition and design features is key to achieving optimal performance with lever valves in industrial sectors.

Maintenance Tips for Ensuring Optimal Performance of Lever Valves

When it comes to maintaining lever valves for optimal performance in industrial applications, regular inspections and proper care are key. One essential tip is to routinely check for any signs of wear and damage. Inspect the valve handles, seals, and seats for any degradation or obstruction. This proactive approach helps catch potential issues before they escalate, ensuring the valve operates smoothly and efficiently.

Another important maintenance tip is to keep the valves clean and lubricated. Debris buildup can lead to performance problems and affect fluid control. Regularly clean the exterior and interior components, and apply appropriate lubricants to moving parts to prevent stiffness and ensure ease of operation. This simple step can significantly extend the lifespan of the lever valve and enhance its overall functionality.

Lastly, consider the environment in which the valves are operating. If they are exposed to harsh chemicals or extreme temperatures, it’s crucial to select materials that can withstand these conditions. Choosing the right valve construction materials and implementing appropriate protective measures will help maintain optimal performance and reliability in challenging industrial settings.

Related Posts

-

Unlocking Efficiency: How Lever Valves Can Reduce Energy Consumption by Up to 30% in Industrial Applications

-

The Complete Guide to Understanding Lever Valves and Their Applications in Modern Engineering

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide

-

Understanding the Importance of Gas Valves in Home Safety and Efficiency

-

Unveiling the Benefits of 4 Check Valve in Industrial Applications with Expert Insights

-

Understanding How Automatic Recirculation Valves Enhance System Efficiency and Performance