What are the Best Mechanical Valves to Use in 2026?

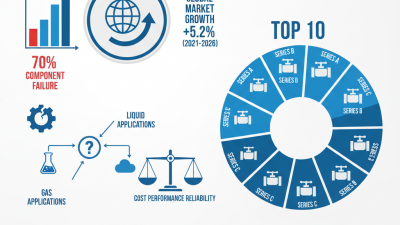

As we approach 2026, the demand for reliable and efficient mechanical valves grows. These components play a vital role in various industries. Choosing the right mechanical valve can significantly impact system performance.

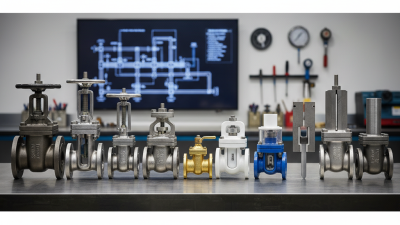

Mechanical valves come in various types and designs. Each type serves specific functions and applications. Some valves excel in fluid control, while others focus on pressure regulation. Understanding these differences is crucial for optimal selection.

However, not all valves are created equal. Some users may face challenges in finding the best fit. It’s important to evaluate features like durability, cost, and efficiency. Considering these factors will lead to better decision-making. In a rapidly evolving market, staying informed is essential. Mechanical valve advancements often reflect industry needs and technological improvements.

Best Material Choices for Mechanical Valves in 2026: A Comparative Analysis

When considering the best materials for mechanical valves in 2026, several factors come into play. The balance between durability and weight is crucial. Stainless steel offers high strength and corrosion resistance, but its weight can be a drawback in some applications. Alternative materials like PVC and HDPE are lighter, yet they may not withstand high-pressure environments effectively. It's essential to analyze the specific use case before making a choice.

Another interesting option is bronze, which provides excellent wear resistance. However, it can be more expensive and might not be necessary for all applications. Each material has its pros and cons. For instance, while polymer valves are lightweight and resistant to corrosion, they may not handle extreme temperatures well. This could lead to failures that require costly repairs.

It's worth noting that emerging materials like composite plastics are gaining attention. They could potentially combine the best of both worlds. Still, they require thorough testing to ensure reliability. Manufacturers might face challenges in a real-world setting. Material selection isn't just about performance; it's also about understanding how they interact with the environment and process fluids. Reflecting on these aspects can lead to better decision-making in valve design and procurement.

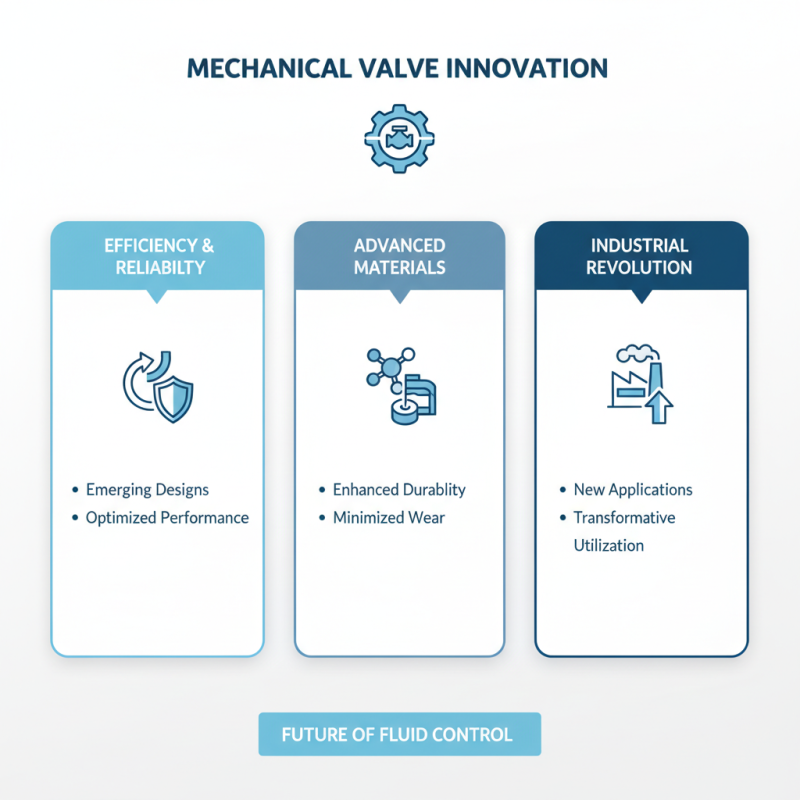

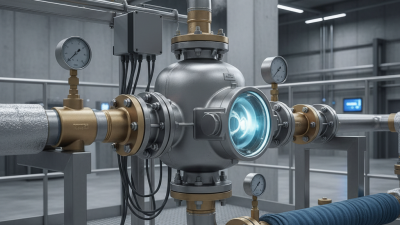

Innovative Designs in Mechanical Valves Expected to Lead the Market

The mechanical valve market is witnessing rapid innovation. Emerging designs focus on efficiency and reliability. New materials enhance durability while minimizing wear. These advancements may revolutionize how industries utilize mechanical valves.

Hybrid valve technology is becoming popular. It combines features from different valve types. This design allows for greater flexibility in various applications. Users report improved performance in demanding environments. However, some designs may present complexity, leading to installation challenges.

Moreover, smart valves are integrating with IoT technology. These valves provide real-time data for better management. They adapt to changing conditions automatically. As useful as they are, reliance on technology poses risks. Users must continually assess the balance between automation and manual control. Innovative designs offer great potential but also require careful consideration.

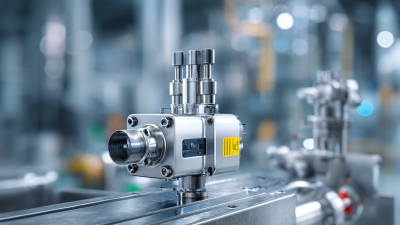

Key Performance Metrics for Evaluating Mechanical Valves in 2026

When evaluating mechanical valves in 2026, several key performance metrics stand out. The flow rate is crucial. It determines how much fluid can pass through the valve efficiently. A high flow rate often indicates better performance in real-world applications. Leak tightness is another vital metric. A valve that leaks can lead to significant losses. Companies should assess this during testing.

Durability is often overlooked. Mechanical valves need to withstand harsh conditions. This means resistance to corrosion and wear. If a valve fails early, it impacts the entire system. Ease of maintenance also matters. Valves that require frequent repairs or adjustments disrupt operations. Companies want reliability with minimal downtime.

Finally, the size and weight of the valve should be considered. A compact valve can save space in tight installations. However, a heavy valve can strain mounting points. Choosing the right balance is essential. As these metrics evolve, industry standards will continue to shift. Understanding these elements is critical for anyone making decisions in 2026.

Mechanical Valve Performance Metrics (2026)

Sustainability Trends Influencing Mechanical Valve Manufacturing

The mechanical valve industry is changing. Sustainability is now a key focus. Manufacturers are seeking greener materials and processes. This shift is reflected in their choice of raw materials. More eco-friendly options, such as recycled metals, are becoming popular. These materials not only reduce waste but also maintain performance standards.

New technologies also play a role. Automation in manufacturing is improving efficiency. Yet, the energy used in production still raises concerns. Balancing energy consumption and output is a constant challenge. Many companies are exploring renewable energy sources. This could lead to lower carbon footprints in the long run.

However, the transition to sustainable practices is not without issues. Some manufacturers struggle with the cost of new materials. The benefits are clear, but immediate demand can limit progress. Finding a middle ground is essential for future growth. Embracing sustainable innovations while maintaining quality remains a complex quest for many in the industry.

Industry Standards and Certifications for Mechanical Valves in 2026

As we approach 2026, the industry standards for mechanical valves are evolving. These standards ensure safety, reliability, and efficiency across various applications. Compliance with ISO norms and ASTM guidelines is crucial. Manufacturers are increasingly focusing on these certifications to meet market demands.

Valves need to withstand extreme conditions, from high pressures to corrosive environments. Testing processes should verify performance under these circumstances. While some valves excel in standard applications, they may falter in specialized uses. Each application has unique requirements that should not be overlooked.

The importance of traceability in valve manufacturing cannot be understated. Documentation and testing results should be readily available. However, inconsistencies in reporting can lead to confusion. It is essential for stakeholders to demand transparency. The path to improving valve standards is ongoing and requires constant vigilance.

Related Posts

-

2026 Best Valve Products for Efficiency and Performance Review?

-

Top 10 Apollo Ball Valves for Your Next Project?

-

Top 10 Gate Valves Types and Their Best Applications for Your Projects

-

What is a Recirculation Valve and How Does It Work?

-

Top 10 Tips for Choosing the Best Valve Suppliers for Your Projects

-

How Automatic Valves Revolutionize Industrial Automation: A Comprehensive Guide